A company that challenges and innovates based on principles and trust

PRODUCT

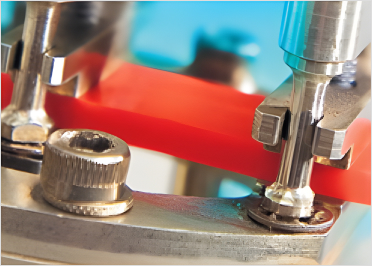

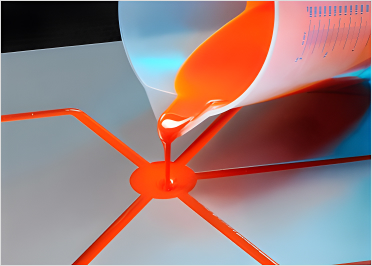

Cast Polyurethane

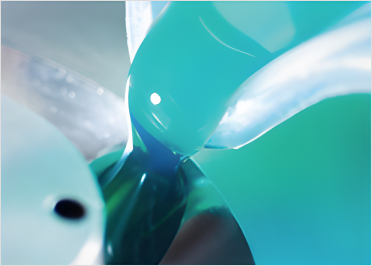

Cast polyurethane is an elastomer produced through casting with using raw materials such as diisocyanates, polyols, and curing agents. It can be manufactured in a wide range of hardness and offers advantages including wear resistance, elasticity, tear strength, oil resistance, solvent resistance, and ozone resistance.

Due to issues related to storage, handling, and toxicity, diisocyanates are supplied as prepolymers, which are formed by reacting diisocyanates with polyols. Cast polyurethane systems are typically classified into two-component systems (prepolymer and chain extender/curing agent) and three-component systems (prepolymer, polyol, and curing agent).

Supplier

-

Covestro Elastomers

Covestro Elastomers, the successor of Bayer, the original developer of polyurethane, offers a wide range of high-performance raw materials and specialized customer support based on its innovative raw material systems. As the only global company that also manufactures Baulé® molding machines, which best implement these systems, Covestro Elastomers provides a "One Single Source" service.

Choyang Chemical, as the distributor of Covestro Cast PU, supplies products from various factories in France, Spain, China, and other locations. Through its Tech Center, equipped with molding machines for demonstrations, and a logistics center with reliable inventory, offers the best services to its customers.

SYSTEM

Two-Component System

This system is designed to produce PU with a single hardness using pre-synthesized prepolymers,

which are made from diisocyanates and polyols, and curing agents.

Diisocyanate TDI, MDI, or others

Polyol (long chain) Ether, Ester, or others

Prepolymer

Chain Extender (short chain) Moca, BDO, or others

Polyurethane

Three-Component System (Quasi-prepolymer)

The Quasi-prepolymer is a prepolymer based on MDI, with more than 12% unreacted NCO content remaining.

This system allows for the production of PU with varying hardness levels by adjusting the proportions of polyol (long chain) and curing agent (short chain) during the casting process.

Diisocyanate MDI

Polyol (long chain) Ether, Ester, or others

Quasi-Prepolymer

MDI-Ether

or

MDI-Ester

Polyol

Ether

or

Ester

Chain Extender BDO

Polyurethane

Characteristics

The properties of cast polyurethane (PU) are determined by the type of diisocyanate (TDI or MDI) and polyol (Ether or Ester) used in the prepolymer.

Regarding the diisocyanate

| TDI | |

|---|---|

| Advantages | Drawbacks |

|

Low moisture sensitivity Easy mixing Easy process Easy to reach high hardness Linear reaction kinetics |

Difficulty to reach low hardness Toxicity |

| MDI | |

|---|---|

| Advantages | Drawbacks |

|

Adjustable pot-life Low toxicity Hydrolysis resistance Large range of hardness |

Sensitive mixing and process Exponential reaction kinetics |

Regarding the long chain polyol

| Ether Polyol | |

|---|---|

| Advantages | Drawbacks |

|

Hydrolysis resistance Microorganism resistance Low temperature behavior Resilience |

Solvent resistance Tear resistance |

| Ester Polyol | |

|---|---|

| Advantages | Drawbacks |

|

Solvent resistance Hydrocarbon resistance High temperature behavior Tear resistance Abrasion resistance |

Sensitive to hydrolysis Sensitive to microorganism Low resilience |

Application

-

Renewable energy

-

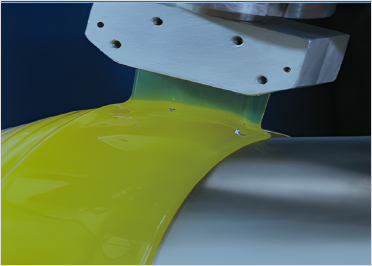

Automotive

-

Material handling

-

Mining and Quarries

-

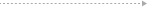

Oil & Gas

-

Pulp & Papaer

-

Printing

-

Industrial

-

Sports & Leisure

Types

-

TDI prepolymer

System with free TDI content under 0.5% enabling excellent mechanical properties, safety with low toxicity, and cost-effective as non-dangerous goods

-

Low unreacted TDI prepolymer

Free TDI content under 0.1% enabling low toxicity, low viscosity, and excellent mechanical properties

-

MDI prepolymer

Moca free, Low toxicity, Wide range hardness, Good hydrolysis resistance, Easy pot life control

-

Quasi-MDI prepolymer

Conveniently produce various hardnesses with single system

-

NDI prepolymer

Low abrasion loss and compression set, High tensile strength, tear resistance, and rebound resilience. Excellent dynamic performance with minimal compression set under prolonged high load and high-speed usage

-

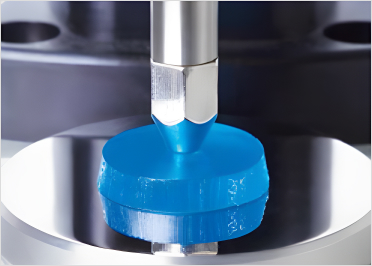

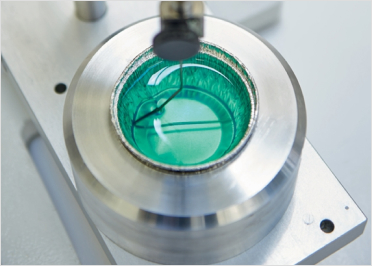

Rotational Casting System

Coating roller without molds using the rotational casting technique. No additional processing steps

-

Cold Casting System

No need to pre-heat molds or post-cure. Low shrinkage and high elongation. Appropriate for prototypes and concrete molds.

-

Customized Systems

A variety of systems developed to meet specific customer requirements.

Young-Yun Kim Senior manager

-

010-8944-6206

010-8944-6206

-

-

suhookim@manhopolymers.com

suhookim@manhopolymers.com

Detailed brochure request contact