A company that challenges and innovates based on principles and trust

PRODUCT

Olefin is an aliphatic unsaturated hydrocarbon that has a carbon double bond in its molecular structure. Polyolefin is a polymer of these olefins.

Supplier

-

Hanwha Solution, which produced LDPE and LLDPE for the first time in Korea in 1972, has the largest LDPE and LLDPE production facilities in Korea and maintains the No. 1 market share in LDPE.

EVA and LDPE, which are high value-added PO products, are produced by the Saudi International Polymers Company (IPC), resulting in cost savings and economies of scale, especially in the EVA sector, with the world's second largest production scale and global competitiveness.

Product descriptions

-

-

01

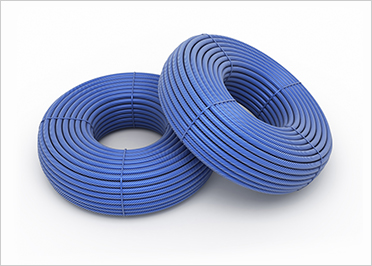

EVA

(Ethylene Vinyl Acetate Copolymer)

-

-

02

LDPE

(Low Density Polyethylene)

-

-

03

LLPDE

(Linear Low Density Polyethylene)

-

-

04

HDPE

(High Density Polyethylene)

EVA is manufactured by copolymerizing ethylene and vinyl acetate, and its elasticity, heat adhesion temperature, durability, and transmittance vary depending on the VA content.

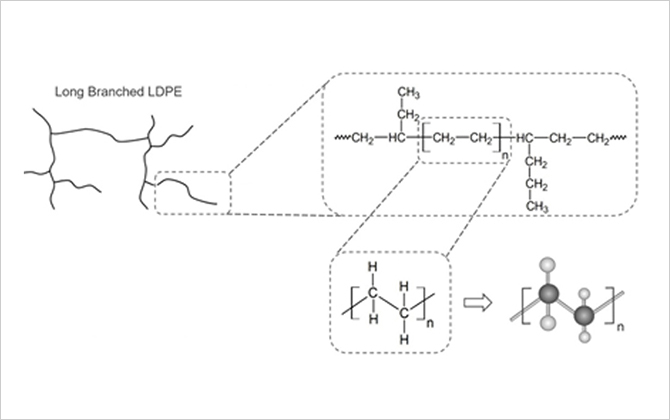

As a synthetic resin manufactured by polymerizing ethylene, LDPE is one of the most widely used general-purpose plastics in everyday life and is used to manufacture transparent film for packaging, wire sheaths, various wraps, etc. due to its excellent processability, flexibility, and transparency.

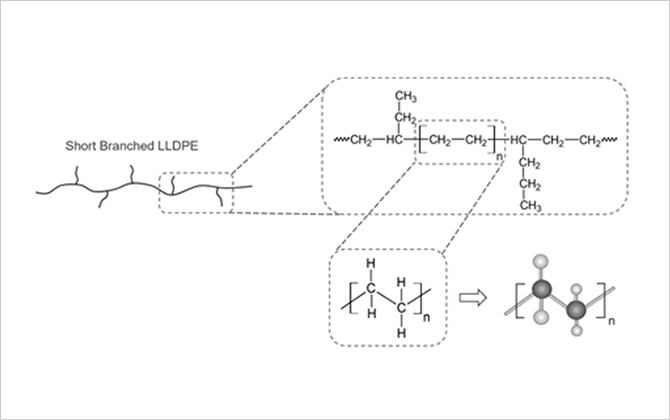

It is called linear low-density polyethylene because its density is low like LDPE and the molecular structure is linear like HDPE. LLDPE is used as a raw material for various industrial packaging materials, food packaging materials, and tarpaulin coatings due to its excellent strength, processability, and excellent optical properties and environmental stress (resistance to unstable cracks during plastic product molding).

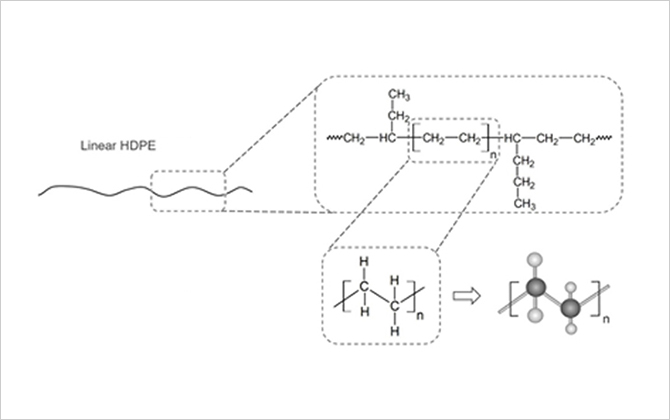

As a synthetic resin produced by polymerizing ethylene, HDPE is one of the most commonly used plastics in everyday life with high impact strength and cold resistance, and is widely used in various containers and plastic boxes.

Product descriptions

| Classification | Grade | Characteristic | Application |

|---|---|---|---|

| Extrusion coating | 1125, 1157, 1159 | Excellent adhesion to equipment and low-temperature heat seal synthesis | Lamination film |

| Foam | 1315, 1316, 1317, 1326, 1328, 1333, 1334, 1340, 2315, 2319 | Excellent mechanical strength and foaming | sponge and sole for shoes |

| Hot melt | 1519, 1520, 1528, 1529, 1533, 1540 | Excellent bonding strength and quality uniformity | adhesive for hot melt |

| Film | 1214, 1218, 2020, 2030, 2040, 2050, 2060, 2240, 2250 | Excellent tensile strength, drop impact strength and optical properties | agricultural film, hot-bed film, shrink film |

| Wire | 1815, 1828, 1834 | Excellent extrusion processability and inorganic filling | compound base resin for wires |

| Classification | Grade | Characteristic | Application |

|---|---|---|---|

| Injection molding | 303, 724, 737, 749 |

|

container lid, household containers, master batch |

| Coating | 950, 951, 955, 961, 963 |

|

soft packaging, paper coating. |

| Film foaming, Blow molding | 830, 5301, 5302, 5303, 5305 5306, 5310, 5312P, 5316 |

|

base resin for electric wire insulation, protective film, blow molding (medical equipment), industrial film, general packaging shrink film, hot-bed film |

| Classification | Grade | Characteristic | Application |

|---|---|---|---|

| Film | 3120, 3121UV, 3123, 3126, 3127, 3224, 3303, 3304 | Excellent tensile strength, tear strength, transparency, and heat-sealing. Excellent workability, optical properties and yellowing resistance | agricultural, general packaging film, thin film, general purpose film, lamination film |

| Injection molding | 7635 | Excellent strength, stress resistance uniformity and gloss | fender liner |

| Extrusion sheath | 9730 | Excellent high-speed processability, adhesiveness, and heat-sealing strength | tarpaulin |

| Classification | Grade | Characteristic | Application |

|---|---|---|---|

| Silane water crosslinking | 3391 | Excellent elongation and tensile properties | Compound for heating/water supply pipe |

| Yarn | 3392 | Excellent elongation and tensile strength | T-die extrusion Yarn |

| Injection molding | 7600 | Excellent processability, impact strength and hardness | Silicon cartridge, pallet injection molding |

| Cap | 7390 | Excellent workability, impact strength, and cracking resistance | Cap |

| Wire sheath | MD9030, 9031 | Processability and oxidation stability | Wire compound |