A company that challenges and innovates based on principles and trust

PRODUCT

Filler is a solid substance that is added to improve the physical properties of synthetic compounds or lower prices and calcium carbonate, kaolin, talc, silica, etc. are main fillers, which are used for rubber, plastic, paint, resin, etc.

Characteristic

-

01

Cost reduction

It is used to reduce cost by replacing expensive base materials or increasing total quantity.

-

02

Improvement in physical properties or other properties

Proper fillers can improve mechanical, thermal, and other properties.

-

03

Confer a function

Fillers are used to achieve high functionality by giving special functions such as conductivity.

-

04

Improved processability

Fillers are used to improve processability by controlling viscosity and fluidity during processing, preventing mold contamination, promoting mold deformation, and adjusting curing time.

Calcium carbonate is an ionic compound consisting of calcium ions (Ca²+) and carbonate ions (CO₃²⁻) from limestone, divided into Ground Calcium Carbonate and Precipitated Calcium Carbonate, and used as a filler in various applications such as paper, plastic, paint, ink, sealant, adhesive, and cosmetics.

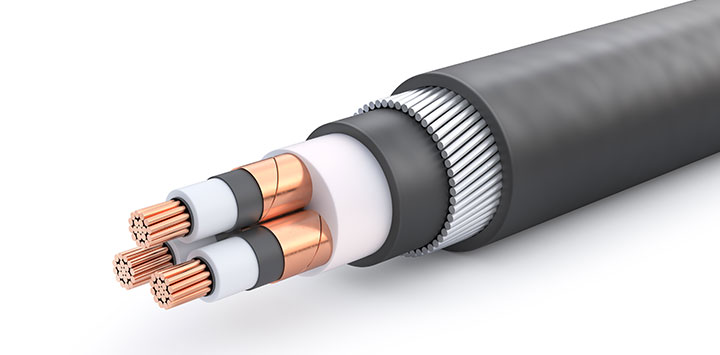

Kaolin is a name derived from the Chinese language of kaolin and is a mineral produced by weathering feldspar for a long time. Hydrated aluminum silicate (Al₂O₃ •2SiO₂ •2H₂O) is white flat and chemically inactive, so it is applied to various industries such as paper, paint, plastic, rubber, wire, concrete, etc

Silica (SiO₂) is a mineral that exists as a major component of sand and quartz, and is widely used as an industrial filler due to its high purity, low dielectric constant and excellent insulation properties, and good processibility.

Talc is a hydrated magnesium silicate, i.e., Mg₃Si₄O10(OH)₂. It is very soft with Mohs hardness of 1, has physical advantages such as electrical insulation and chemical resistance, as well as excellent economic feasibility, so it is widely used in various industries.

Types of calcium carbonate

| Type | Characteristic | Supplier |

|---|---|---|

| Ground Calcium Carbonate(GCC) |

|

Omya, Nitto Funka, Calfine |

| Precipitated Calcium Carbonate(PCC) |

|

Takehara, Dongho Calcium, Eugene Industrial |

Supplier

-

KaMin produces a variety of top-quality kaolin products from a high-purity kaolin mine in Georgia, USA.and supplies them to the global markets.

| Hydrous type | Calcined type | Surface Treated |

|---|---|---|

|

|

|

Product descriptions

| Coatings & Inks | |

|---|---|

|

|

| Plastics & Rubber | |

|---|---|

|

|

| Wire & Cable | |

|---|---|

|

|

| Construction | |

|---|---|

|

|