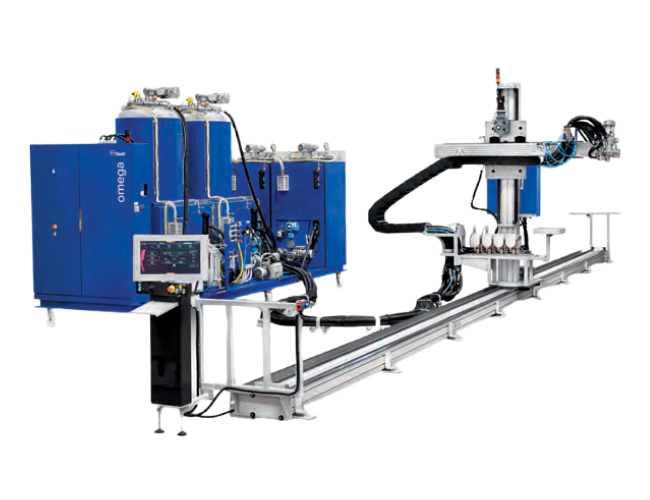

Baulé® Continuous Disc Degasser

Hundreds of degassers are daily used over the world and its reliability is well known. This equipment enables continuous feeding of the machine with degassed material.

It is fully adaptable to any Baulé® machine and avoids production stoppage during material preparation. Furthermore, it automatically delivers required amounts of material and minimizes heat degradation while there is no material stagnation. Two models are available in our range with an output up to 5kg/min or 10kg/min.